When Palmetto State Armory released their Sabre-10 line of rifles, they were clearly marketed towards those collectors and shooters who wanted a heavily military-inspired M110 clone, but without the astronomical price associated with authentic KAC products. The Sabre AR-10, as shown, is a very close approximation of the Knights Armament M110, with only a handful of (mostly aesthetic) differences.

PSA offers a few versions of the Sabre AR-10. Black and FDE models are available, as are .308 Winchester and 6.5 Creedmoor chamberings. Further, both billet (SR-25 slant cut) and forged (rounded rear receiver cut) flavors are on tap. The Sabre-10 doesn’t conform to DPMS high or low specs, using instead PSA’s proprietary rail height that’s very close to DPMS’s low. The barrel uses LR-308 extensions.

The gas block is adjustable with seven settings via a front-mounted knob. This knob takes the place of the rear suppressor attachment point found on the true M110 gas block. The PSA flash hider is both visually and functionally distinct from the KAC unit, offering an open three-prong design instead of the vintage closed tine system, and doing away with the front suppressor mounting point that was rendered obsolete by the gas block change. The three tines of the flash hider are all different lengths, eliminating the tuning fork issue that was commonplace decades ago.

The charging handle is a Radian Raptor-LT with a little PSA branding added. Takedown pins come courtesy of Battle Arms Development. The grip is excellent, with far more texturing than most manufacturers go for.

The Sabre AR-10 features a two-stage trigger that deserves a lot more attention in the marketing materials than it’s getting. I have a box full of spare match triggers for review guns like this one, but I’m sticking with Palmetto’s excellent trigger. It’s that good.

The Sabre AR-10 also has an ambi safety and bolt release.

All told, the Sabre AR-10 looked fantastic during the workbench once-over I normally give new guns before hitting the range. Fit and finish are very nice, and all the bases are covered. Even the BCG’s gas key is overdone with OCKs fasteners.

Range Days With The Sabre-10A1

For the first few range days with the Sabre AR-10 I mounted up a (discontinued) PSA 5-25x scope, brought a variety of ammo, and used mags from Magpul, Mission First Tactical, and Duramag. After getting a rough zero at 25 yards I shot a bunch of 5-round groups at 50 and 100 yards,

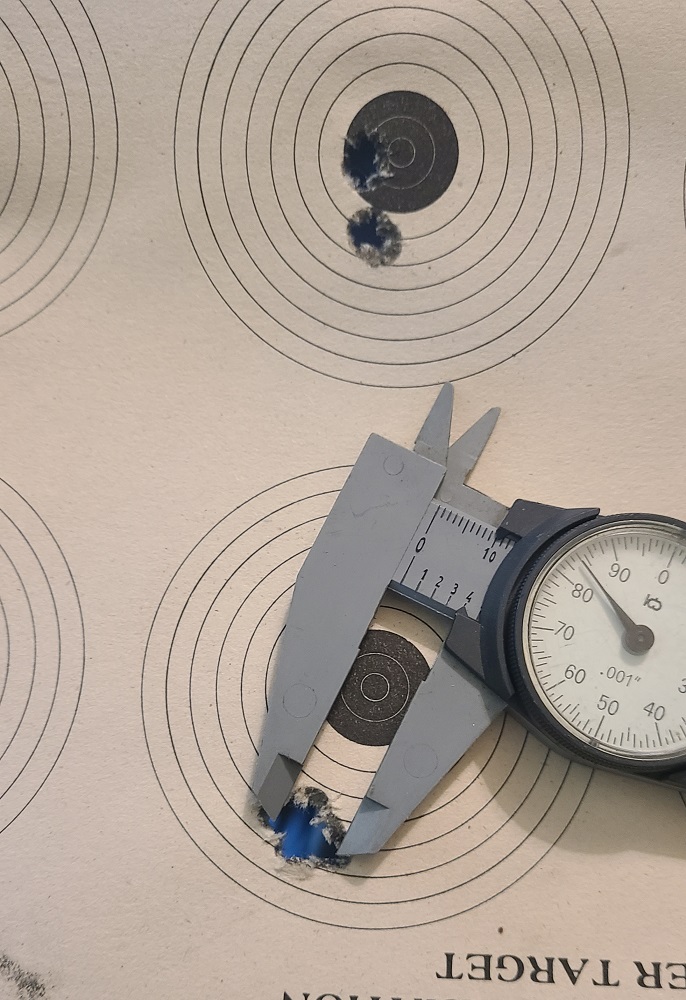

The groups were occasionally amazing and routinely excellent. These clusters ranged from ~.6 MOA to 1.8 MOA, preferring the Winchester 168gr match ammo and Federal 168gr Gold Medal Match. Accuracy was almost always around 1 MOA unless I felt myself rushing the last couple rounds in a string.

As I may have mentioned, I love the Sabre AR-10’s trigger. PSA should definitely offer this as a drop-in accessory on their site. I twisted off the Sabre flash hider and tossed on an AAC suppressor mount for the 762SDn-6. Adjusting the gas was as easy as twisting the knob a couple clicks towards “restricted flow.” The gun continued running well. Further experimentation showed I’d guessed the right adjustment the first time.

The Sabre AR-10 definitely doesn’t kick much, whether in the lead sled, on a tripod, off a bipod, or shooting while standing. The gun’s 10+ lbs. of heft certainly helps cut down on felt recoil, as does a well adjusted gas system.

The Sabre didn’t run 100% reliably out of the box, owing to an overzealous extractor spring. While I had a spare bolt to keep the gun going as needed, PSA eventually helped me suss out the issue without needing to send the bolt back.

What’s Next?

PSA offers this rifle as a near M110 clone, but I wanted even more M110 goodness. With a pile of parts including an M110 gas block from HTX Concepts, a MGL-110 suppressor from Griffin Armament, and an M110 barrel from Rainier Arms, I sent the whole package off to D. Wilson. The gun is transformed now into a very close facsimile of the original military issued rifle with details and performance to be covered in a future article. Here’s a preview pic, though.

Wrapping It Up

The Sabre AR-10 by Palmetto State Armory is still a relatively new variant of Stoner’s AR-10 platform. But this rifle is one that’s well built, accurate, and as shown by my next article preview, set up for further customization. While there was the minor issue of the extractor having too much tension, it was easily remedied and only presented a small black mark on an otherwise excellent review process.

If you’re in the market for a large frame .308 or 6.5 Creedmoor AR platform rifle with “close enough” M110 styling, the Palmetto State Armory Sabre AR-10 runs $1,249.99, and comes with one magazine. If I had left the rifle in stock configuration, I’d be very happy with it’s performance. As it stands, I’m even more excited for where this rifle is heading.

Specifications: Palmetto State Armory Sabre-10 Rifle

- Barrel Length: 20″ Fluted

- Gas System: Rifle-Length

- Barrel Steel: 4150 CRMOV

- Barrel Finish: Nitride

- Muzzle Thread: 5/8×24

- Chamber: .308 (6.5 Creedmoor available)

- Twist Rate: 1:10

- Gas Block Type: Picatinny Adjustable Gas Block – Pinned

- Muzzle Device: Sabre Compensator

- Receiver Material: Billet 7075

- Hand Guard Type: 12.5″ Quad

- Bolt Carrier Group: Sabre AR-10 BCG with Sprinco Gas Rings, Sprinco Ejector Spring, Sprinco Extractor Spring, and OCK’s Gas Key Fasteners

- BCG Finish: Hard Chrome Finish

- Charging Handle: Radian Raptor LT

- Lower Material: 7075 with Built in Ambi-Bolt Release

- Takedown/Pivot Pin: Battle Arms Development AR-10

- Trigger: Sabre Two-Stage Black DLC Coated

- Buffer:Rifle Length AR-10

- Buffer Spring: AR-10 Rifle Length Spring

- Safety: Radian Talon 45/90 Safety

- Pistol Grip: Sabre Grip

- Stock: A1 Stock

- Finish: Black

- Furniture Color: Black

“Even the BCG’s gas key is overdone with OCKs fasteners.”

That’s attention to ‘reliability detail’. OCKs screws are less likely to loosen (i.e. practically impossible to ‘self loosen’ from vibration forces on their own over time, remember, the BCG is slamming back and forth a lot) after staked properly because the metal deforms into the ridges on the screws, unlike the others where the screw heads are smooth. Its a key ‘failure’ and ‘hard to diagnose failure’ point in AR’s – the smooth screws loosen a little over time, ever so slightly, as the smooth surface of the screw heads ‘slips’ in the metal staking and you end up with a gas leak from under the gas key – leading to random odd problems happening like, for example, a FTE for certain grades/brands of ammo.

For example – just one example as the issue can manifest in different ways: A lot of people with suppressors or firing hotter match loads, with ‘smooth’ head screws on their BCG’s experience these ‘random issues’ and don’t realize it so they change the BCG out and the problem seems to go away. So they blame the BCG as being junk when in reality the BCG/bolt are fine and all they needed to do was get a new gas key and some OCKs screws, seal the key surface with some green loctite or gasket sealant, and torque to value then stake properly instead of spending a lot more, or more extra, money on a new BCG. The higher back-pressure of a suppressor or the higher pressure gas from match loads will cause it to happen where normal target loads don’t – it could be a sign that the screws are loosening by the smooth head of the screw slipping past the staking just enough that under the increased pressure the gas leaks from the bottom of the gas key where it meets the BCG. And sure, it could also be that the screws were not torqued to the proper value, or the staking wasn’t properly done, or the bottom of the carrier key was not actually flat and smooth, but the top of the list for BCG’s with gas key smooth head screws that are properly staked is the screws are loosening by the smooth head of the screw slipping past the staking just enough. OCKs screws address this and increase reliability.

Note for above: The ‘smooth screws’ to which I am referring are the either ‘smooth head’ cap screws or the ones with very shallow knurling ridges found frequently on gas keys.

OCKs stands for ‘Optimized Carrier Key Screws’. The OKCS screw has sharp, deep, and effective knurling with 12 deeper splines. This allows for metal to flow into the sharp, deep, knurling of the OKCs when staking, This creates more metal on metal contact thus a more secure screw instead of basically resting against the metal with the ‘smooth screws’ with very little in-between ridge metal for the ones with shallow knurling.